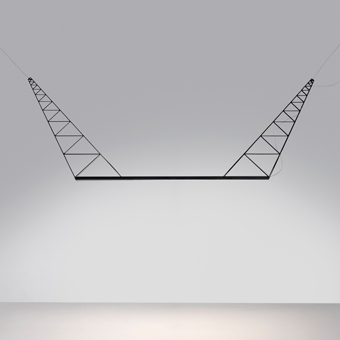

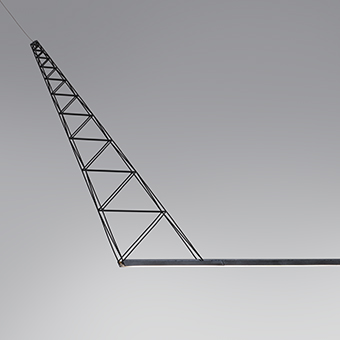

In tensione

- Year: 2014

- Designer: Alberto Meda

- Company: self-production

Pendant LED lamp polyamide 3D printed

3D printers are not particularly new, since 20 years they have been mainly used by industrial designers to make prototypes quickly before making the molds.

But in the last 2/3 years everything has changed for various reasons, the cost of printers has collapsed,

the desire to produce more personal products, non-standard, based on the individual needs emerged, and the scarcity of resources has changed styles to purchase.

The additive technique offers in fact many simplifications and savings of matter, no more a specific equipment such as the mold which, with its mechanical rigidity , imposes a constraint of seriality to recover the fixed costs.

3D printing reduces the need for standardized production, it allows customization.

In a near future we will see less expensive machines, fast and silent with resolutions at levels of nanometers, able to transform different materials, from plastic to wood pulp, to foods , capable of printing also the electronic circuits inside the object.

The factories will have 3D printers alongside milling machines, presses, foundries and plastic injection molding.

In various industrial fields the intersection with these techniques has already taken place, such as the aircraft industry or in the field of Formula 1 car, with titanium powders sintered components.

My interest is to investigate the possibility of using that technique in the field of light because light is dematerialized and in my opinion also the structure that supports it should be light and discreet. In this sense I made an LED 12 Watt power hanging lamp with a sintered polyamide structure .

The lamp can be realized with different lengths, depending on the requirements and also with a dual light source, direct and indirect.

The lamp presented at the Triennale in 2014 in the show " Italian design beyond the crisis, autarky, austerity, self-production", is 1400 m long x 480x 20 mm.

It Weighs 1Kg